Mianyang Yasen Hardware Tools has over 10 years experience in manufacturing wood work drills bits with different kinds: brad point drills(dowel drills),through hole boring bits,hinge boring bits etc. Today we are going to summarize some common problems during use of woodworking drill bits below:

The cause of chipping in the machined hole

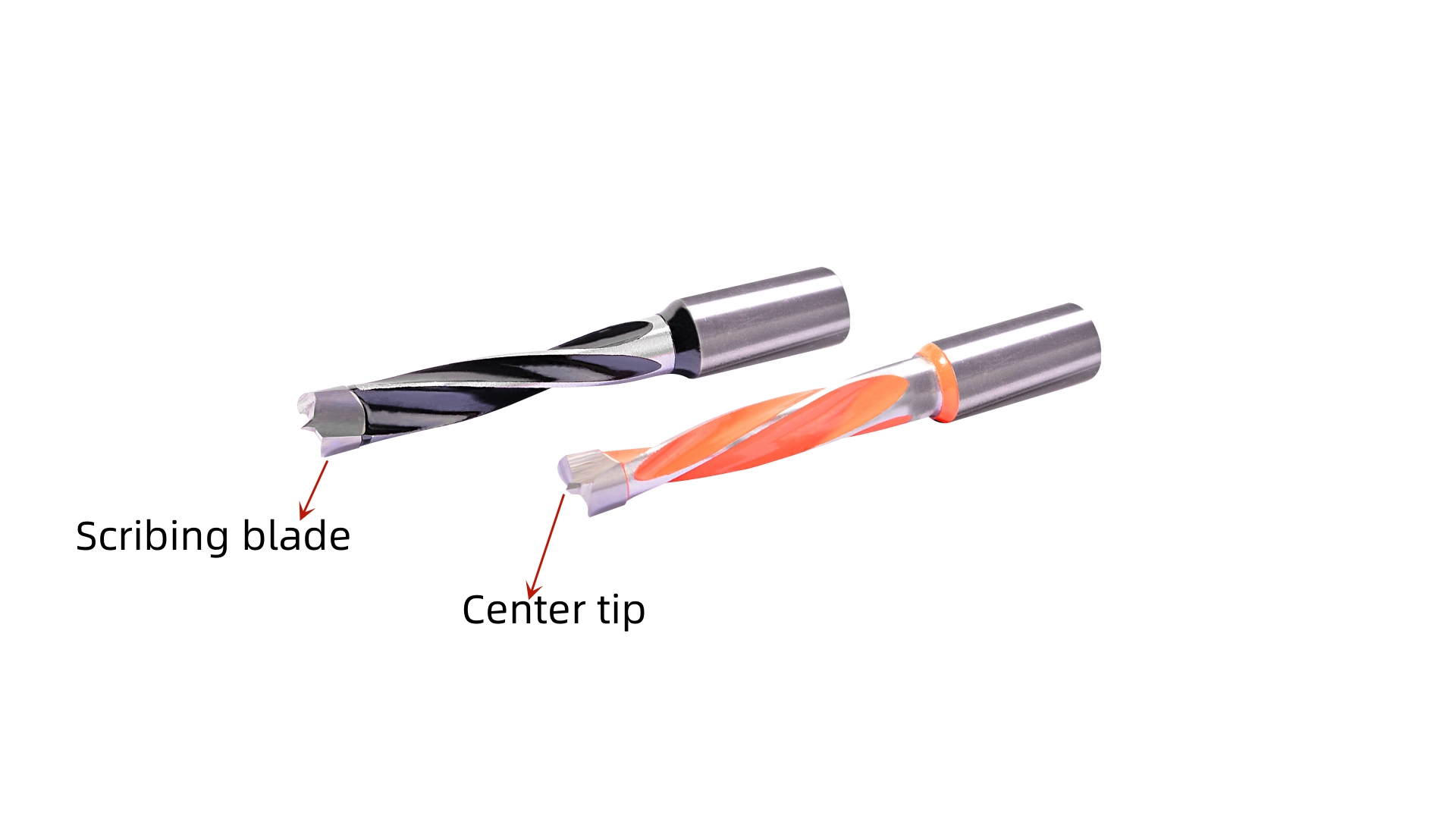

1. The scribing blade is not sharp, and the two scribing blades are not equal in height;

2. The centerness of the center tip and the shank does not meet the standard;

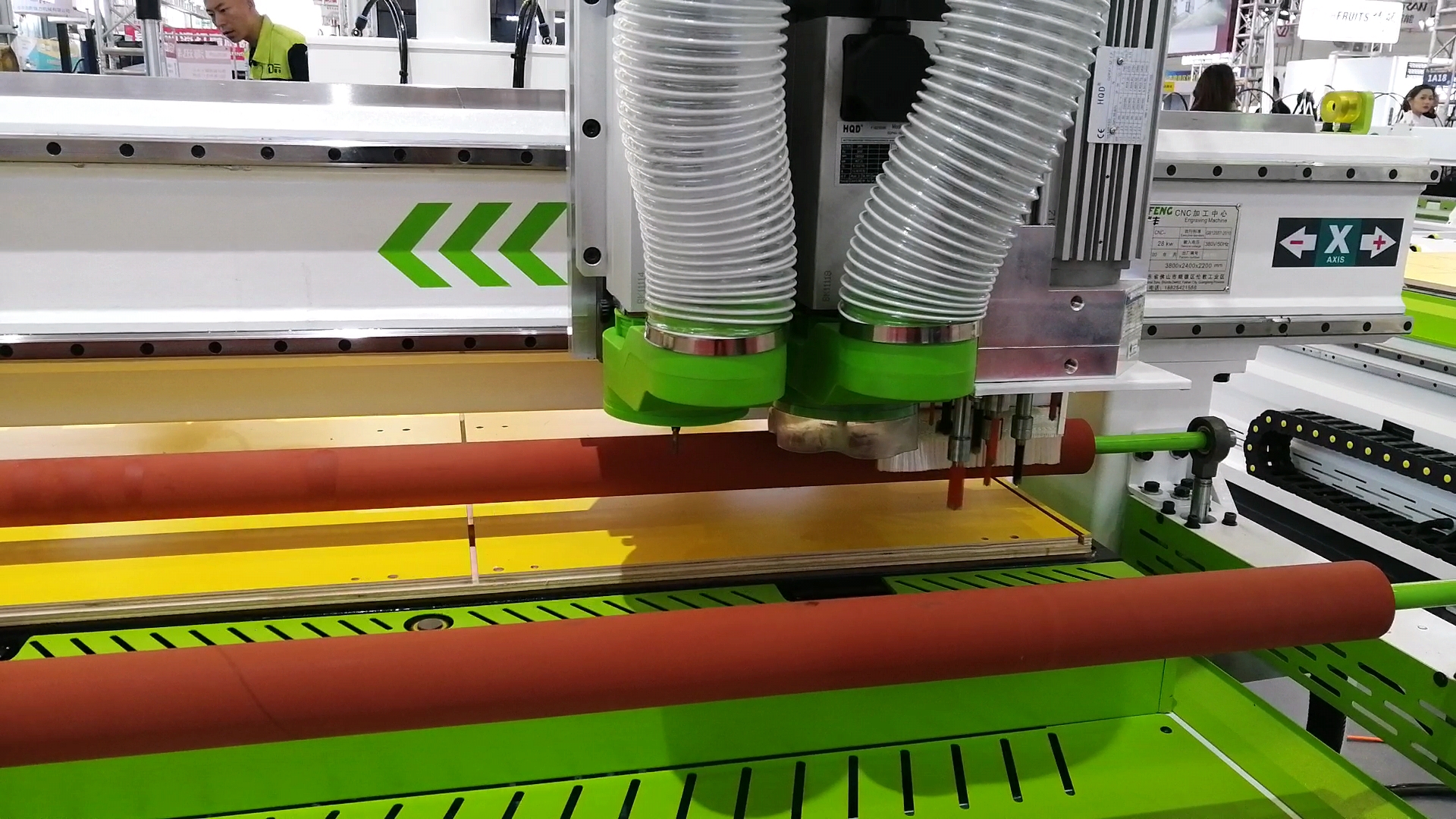

3. The spindle of the machine tool itself has a large runout;

4. The processed plate (workpiece) has a moving phenomenon;

5. The spindle speed does not match the tool feed speed;

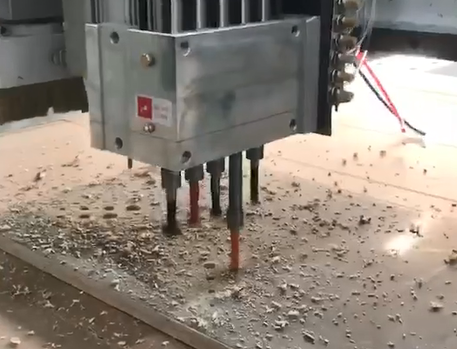

6. The concentricity of the row drill quick coupling is not high or other technical data are not up to standard.

The reason for the elliptical phenomenon of the hole after machining

1. The center tip and the handle are not the same center, or the center tip is not sharp;

2. The workpiece moves during the drilling process;

3. The spindle speed does not match the tool feed speed;

4. The centrality of the row drill coupling is not high or other technical data is not up to standard;

5. The drill seat of the row drilling rig is loose or damaged.

The cause of smoke and paste during processing

1. The knife edge is not sharp, and the drill bit should be replaced;

2. The spiral groove (chip evacuation chute) is blocked, resulting in poor chip removal;

3. The humidity of the workpiece (processing material) exceeds the standard, the plate glue content is too heavy or the glue quality is not good (MDF and plywood are especially prominent)

4. The feed speed of the tool does not match the type of material processed and the depth of the hole;

5.Select the type of drill bit suitable for processing the material.

Address: Mianyang City,Sichuan Province,China

Cell: +86-15386660937

Tel:+86-816-2406189

Fax:+86-816-240619

Email/Skype: joyce.yasendrill@outlook.com

WeChat: YS15386660937

Post time: Nov-05-2022